Wachs SDB 412/2, a hand held beveling machine that delivers maximum power and performance for fast, accurate weld preps on pipe and tube from 4" I.D. thru 12" O.D. (101 mm to 305 mm) pipe or tube up to 1.125” (29 mm) wall.

Face, bevel and counterbore simultaneously on carbon, stainless and high alloy steels.

Benefit from the SDB’s versatility. Machine boiler tube, heavy wall pipe, thin wall tube, prep elbows and face flanges with the SDB 412/2.

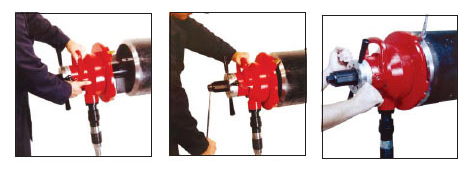

• Set up and operate from storage case to pipe in under 10 minutes.

• “QUICK CHANGE” extension legs use captivated fasteners to mount firmly to mandrel.

• One adjustment, expandable three leg chuck automatically centers and squares the machine in pipe I.D.

• Only 2 operating tools required.

• Install or adjust tool bits in seconds.

• Convenient “Fail safe” on/off motor valve, adjustable hand grip speed control and infeed hand wheel with indices for precise measurement.

• Adjustable dual key design makes tool feed easy, absorbs torque, reduces operator fatigue and increases safety.

• Prep 8" schedule 80 stainless steel pipe in less than 5 minutes.

• Powerful 1-1/2 horse power air motor easily handles 1.125" ( 29 mm ) wall pipe.

• Set up square in elbows, tees, and valves with optional 3 leg fitting mandrel.

• Compact, heavy duty cast aluminum housing is tough yet lightweight.

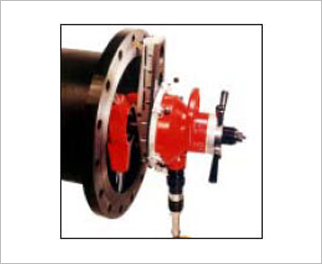

• Four tool rotating head with large “easy to access” tool locking set screws.

• Precision tapered roller bearing and self lubricating bushing maximize machine life.

• High strength, large diameter mandrel shaft and wide surface chuck legs maximize rigidity.

• Right angle air motor placement satisfies minimum clearance requirements.

• Special heat treated ring and pinion gears for demanding pipe prepping applications.

• Corrosion and wear resistant finish applied to external components

Portable pipe prepping machine will face, bevel, compound bevel, j prep, and counterbore using up to 4 tools simultaneously * machine flat face and raised face flanges, record groove (500rms), 250 rms, 125 rms, and 63 rms surface finishes with optional ff 424 flange facing module.

CAPACITY :

Mount in 3.780" (96 mm) i.d. through 12" (304.8 mm) i.d. * machine double extra heavy 5" (127 mm) through 8" (203.2 mm) pipe 1.125" (28.5 mm) wall max. * 10" (254 mm) pipe to sch 160 1.125" (28.5 mm) wall max. * 12" (304.8 mm) pipe to sch 120 1" (25.4 mm) wall max.

CONTROLS :

Manual in-feed with index gauge for precise in-feed and measurement * on/off fail-safe motor lever * speed control valve.

AXIAL FEED :

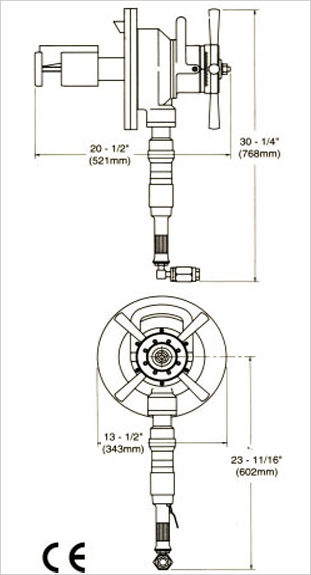

.080" (2 mm) PER REVOLUTION 3" (76.2 mm) TOTAL TRAVEL.

MANDREL :

Self-centering, i.d. mounted, single action 3 blade system with adjustable expansion nut. complete set of 8 “captivated fastener” extension leg sets to cover 3.78" (96.01 mm) through 12.82" (325.6 mm) i.d. pipe or tube.

DRIVE :

PNEUMATIC, HYDRAULIC

AIR REQUIREMENTS :

55 CFM @ 90 PSI (1.6 cu.m @ 6.3 BAR)

HYD. REQUIREMENTS :

8 GPM @1500 PSI

TOOL RPM :

0 TO 30 RPM

TOOLING :

Premium high speed steel insert tools to face, bevel and counterbore. • carbide and custom configuration tooling available upon request.

WEIGHT :

Basic machine without mandrel 51 lbs. (23 kg.) standard mandrel 17 lbs. (8 kg.)

STANDARD EQUIPMENT :

Basic machine and air motor drive * standard mandrel and complete extension leg set * 13.5" (342 mm) o.d. rotating machining head * operating tools * manual * storage case.

OPTIONAL ACCESSORIES :

Fitting mandrel, 3-leg adjustable for elbows, tees, valves and flanges * flange facing module 3.75" (95.2 mm) i.d. to 24" (609.6 mm) o.d. * thin wall i.d. mounting kits for sch 5 &10 * atm “air treatment module” * low clearance tool holder * dial indicator system.