SDB 103 | SDB 206 | SDB 412

E.H. Wachs SDB206/2 is a strong and versatile handheld beveling and prepping machine that delivers maximum power and performance for fast and accurate end preps. The SDB 206 operates on pipe and tube from 2.26” through 6.77” ID, up to 0.75” wall (57mm through 172 mm ID, up to 19.05 mm wall).

The SDB 206/2 will face, bevel, deburr, compound bevel and counterbore simultaneously on carbon, stainless and high alloy steels and will also machine boiler tube, heavy wall pipe, and thin wall stainless tubing. The SDB offers versatility, durability, and a compact and lightweight design, and can be fitted to difficult to prep elbows with the optional independent fitting mandrel.

• Prep schedule 80 stainless pipe in minutes

• Face, bevel, deburr, compound bevel, J-prep and counter bore with the premium highspeed replaceable steel form tools, carbide and high-speed steel insert tooling

• Large bearing load diameter and tapered roller bearings support special heat treated ring and pinion gears for smooth operation and long life of the machine

• Tough, yet lightweight cast aluminum alloy housings for easy handling and performance

• Corrosion and wear resistant finish applied to external components for protection against the elements

• Buy Wachs replacement tooling at a fraction of what the others cost

• Maximized rigidity — large diameter mandrel shafts and wide surface chuck legs

• Large diameter mandrels and increased area load bearing surface areas create a rigid powerful tool to perform precision bevels on heavy wall pipe applications

• Easily machine heavy wall pipe with the powerful 1-1/2 HP high torque low speed air motor

• Machine raised groove or smooth 63 RMS finish

• Easily operate handgrip speed control and precision feed hand wheel

• Minimal clearance required

• Converts from beveler to flange facer

• In less than 5 minutes with quick-change legs

• Automatically center with 3-leg chuck

• Install tool bits in seconds

• Safely operate with the “fail-safe” on-off motor valve

• Compact and lightweight design

PIPE CAPACITY

• 2.27” ID to 6.77” ID (up to 9.63” with extended range kit)

• 57.66 mm ID to 171.96 mm ID (up to 244.68 mm with extended range kit)

PIPE WALL THICKNESS :

Up to 0.75” (19.05 mm)

CONTROLS

• Manual feed with index gauge for measurement

• On/off fail-safe motor lever

• Motor speed control

FEED RATE :

0.08” (2.12 mm) per revolution

FEED STROKE :

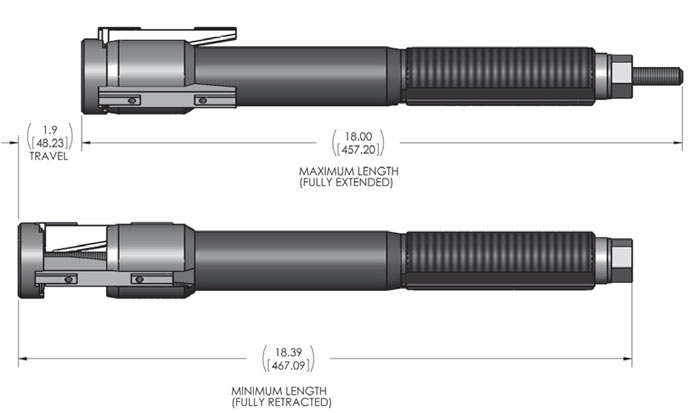

2.5” (63.5 mm) usable feed travel

DRIVE OPTIONS

• Air 70 cfm @ 90 psi (33 l/s @ 6.2 bar)

• Hydraulic 8 gpm @ 1500 psi (30 lpm @ 103 bar)

• Electric (110 V or 220 V)

TOOL RPM :

0 to 40

TOOLING :

Standard or high-range tool holder with high-speed steel inserts; carbide available

TOOL SLOTS :

4 (all rotating head options)

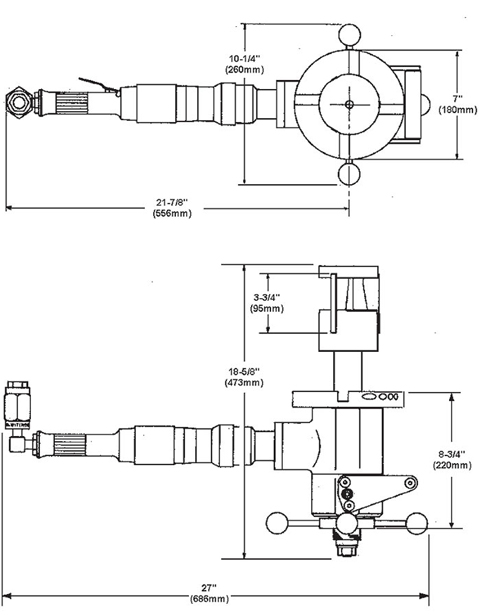

DIMENSIONS :

• Length: 9” without mandrel; 19” with mandrel

(228.6 mm without mandrel; 482.6 mm with mandrel)

• Width: 11.5” (292.1 mm)

• Height: 27.5” with air motor (698.5 mm with air motor)

WEIGHT :

42 lb with mandrel and air motor (19.05 Km)

• Rugged, job site friendly storage case

• Standard mandrel

• Complete extension leg set

• Operating tools

• Manual

• Extended range kits for 6.71” ID through 9.63” OD

• Small mandrel for 1.91” ID through 2.46” ID (48.51 mm ID through 62.48 mm ID)

• Optional flange facing module

• Short perch independent fitting mandrel

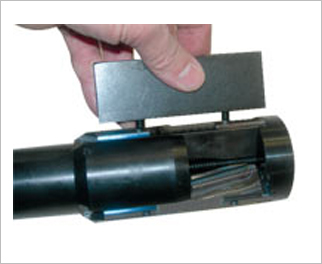

• Collet mandrel for thin walled applications

• Electric drive motor

• Rotating tool holders expand low range and high range prepping capabilities

• Air filtration to eliminate water and airborne particles

• Available custom tooling

• Hardened steel chuck body

• Enhanced chuck legs are more durable for superior operation

• New design clamping drawbar

• Thicker extension legs

• Captivated hardware

• Re-sharpening service with 24-hour turn around

• Rental options for short-term needs

• Lease to purchase programs

PART NUMBERS

• Air Powered 56-000-01

• Electric Powered 56-000-02

• Hydraulic Powered 56-000-03

• Mandrel Upgrade Kit 56-310-00

• Flange Facing Package 56-000-FF