Thanks to many years of experience the Eckelmann CNC core contains broad range of functions, continuously extended based on DIN 66025. The integration of typical technological and geometrical requirement makes a very broad range ofapplications possible.

The CNC core also supports the most sophisticated multi- channel CNC applications with cycle times less than 1 msec. PLC functionality is already integrated. The wide range ofinterfaces meets all requirements for connection of I/O modules and drives.

Eckelmann AG engineers support their customers in thetechnology - specific design of user interfaces and control units. In this way, proven functionality is combined with user - friendly design.

• Reverse travel with returning to the contour.

• Interrupts with subroutine processing

• Block search for starting anywhere on the contour

• Speed dependent analog output for power control

• Transformations (5/6 axis) for differing kinematics

• 3D Axis correction

• Path dependent switching functions

• Technology specific functions

Numerous machine manufacturers andusers from widely varying fields ofapplication (grinding, cutting, handling,profile processing, forming, etc.) place their trust in the proven abilities of Eckelmann CNC.

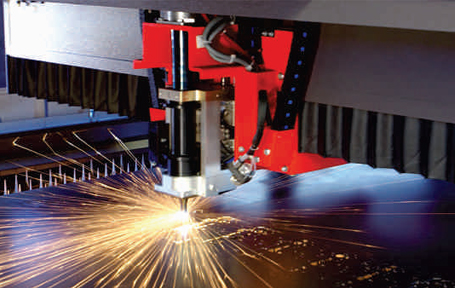

Eckelmann offers the EOCUT all-inclusive package "CNC for cutting” as the state of the art solution for these industries.

Both the respective HMI module and the NC and PLC operating system offer numerous functions which are adapted to the typical

requirements for cutting with the widest possible variety of cutting tools.