Authorised Channel partner for OMCA

Description

Frame in steel and aluminium casting.

Hardened work plate with sliding rollers.

Motorized feeding with two polyurethane wheels (90 shore).

Trolley complete with height adjustment devices, chips protection, chip box, and swivel wheels with brake.

Possibility to work with the trolley lifted in the presence of irregular floor.

Possibility to work also without trolley.

| Motor power | Trifase 230/400 Volt, 4kw, 50/60 Hz, 4 poli |

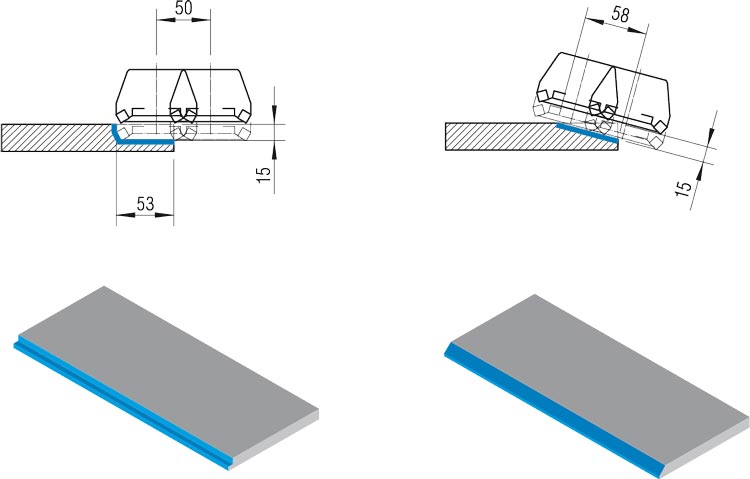

| Width bevelling (X axis) | 53 mm |

| Depth bevelling (Z axis) | 15 mm |

| Chamfering angle | From 90° to 75° |

| Plate thickness | From 8 mm to 100 mm |

| Cutter | Ø 63 mm Z 7 |

| Cutter speed | 900 RPM |

| Chamfering speed | from 0 to 1 mt/min |

| Working height | 930 mm ÷ 1120 mm |

| Working direction |  |

| Dimensions | 760 x 750 x h 2100 mm |

| Application | Steel, stainless steel, cast iron, aluminium, alloy titanium, hardox, super duplex and so on |

| Weight | Kg. 390 |

| Packing dimension | mm 2150 x 1150 x 1100 h - Kg. 455 |

| Sketch | .jpg) Art. 844 Art. 844 |

| Diameter | Ø63 mm H=40 mm Ø=22 mm (1x) |

| Insert | ISO SDHT09 12,7x12,7 Thickness 4,76mm |

| N° | 7 |

| Material | WIDIA |

| Insert code | 865/R |

| Option | For light alloy 865/A |

Special versions

• Plate thickness 8/220 mm