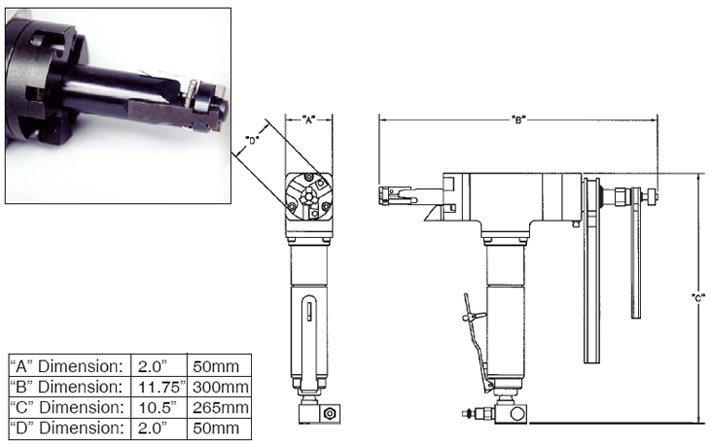

Introducing Wachs new “SB” low profile beveling machine designed for work environments where size and clearance are a machining problem.

The SB delivers maximum power while offering reduced size and weight. Weld prepare tubes and pipe from .69” I.D. to 2.25” O.D. (17.53mm to 57.15mm) up to .375” (9.5mm) wall quickly and accurately.

• Easy to use feed and clamping ratchets

• Captivated clamp leg sets

• Self centering Mandrel & squaring

• Wedge style “tool locking” system

• 3 tool rotating head

• Torque free operation

• 6’ hose whip with swivel standard

• Smallest and lightest beveler in its class

• Minimal side clearance required for use in tight areas

| Machining Function: | Tube and pipe weld preparation |

| Capacity: | Machine tube and pipe .69” I.D. to 2.25” O.D. (17.53 to 57.1mm). |

| Feed: | Manual ratcheting |

| Drive: | Pneumatic |

| Air Requirements: | 25 cfm @ 90 psi 0.7 m³/min @6.2 bar |

| Air motor: | .4 HP |

| Tooling: | High speed steel form tools |

| Mandrel Range: | .69” to 1.82” I.D. (17.53mm to 46.2mm) |

| Installation: | 5 minute set up. Less than 30 seconds change over from tube to tube |

| Weight: | 7.9 lbs. (3.6kg) |

| Controls: | Manual ratcheting tool in-feed. On/Off hand grip with safety |

| Standard Equipment: | Basic SB machine, air motor, 6’ hose whip w/swivel, cutting head, standard mandrel with leg set, installation tools, storage case and operating manual. |