DESCRIPTION

The Wachs EP 424 with the patent pending new Speed Prep auto feed system is a precision I.D. mount end prep machine tool designed to bevel, compound bevel, J prep, face and counterbore pipe, fittings and valves. Utilizing our revolutionary mechanism that feeds simultaneously in the axial and radial planes, it’s able to machine any bevel or compound bevel without templates, incline tool slides or work stoppage. The EP 424 is powerful enough to form tool from 4” to 16” (DN100-400) through Schedule 160, and single point from 4” to 24” (DN100-600) up to a 6.5” (165mm) wall thickness.

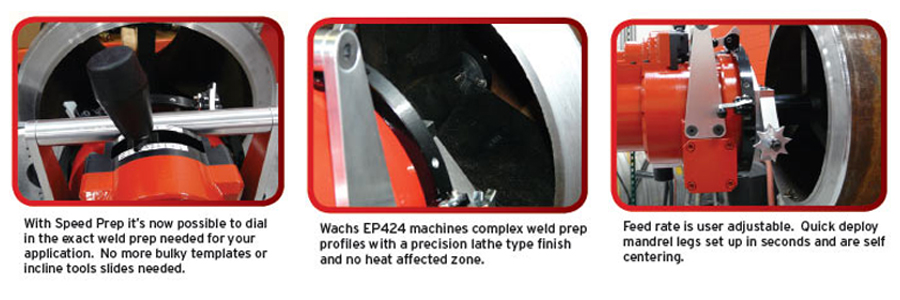

Prior to the EP 424, most end prep machines required a mechanical template or incline tool slide to reproduce the complex preps called for by today’s processes. With E.H. Wachs Speed Prep system, it’s now possible to dial in the bevel angle and the land that works best for your application, all without work stoppages or additional components. The Speed Prep system is engaged by simply pulling the feed handle outward. This advanced feed mechanism creates the exact profile hands free with a ready to weld lathe quality finish and no heat affected zone. For simple form tool usage or as a dedicated flange facer, the Wachs EP 424 is also offered without the Speed Prep auto feed system. More versatile and powerful than any other machine of its kind, the Wachs EP 424 sets the standard in user friendly large diameter end prep machines.(DN = Metric Nominal Diameter)

EP424 FEATURES

• CSpeed Prep design feeds automatically in the radial and axial planes

• Dial in the exact bevel, compound bevel and land that works best for you

• Manual feed handle pulls out to engage Speed Prep auto feed system

• Low friction bearing system provides maximum stability and eliminates chatter

• Fully modular construction for fast, easy one man set up and operation

• EP 424 eliminates the need for accessory templates or external tool slides

• Available without Speed Prep for form tooling and facing operations

• Machines perfect preps from 4 to 24 inches O.D. (DN100-600)

• Form tool from 4 to 16 inches O.D. (DN100-400) pipe

• Delivers a lathe quality finish, ready to weld with no heat affected zone

• Mounts to I.D. of pipe with easy to use self centering mandrel system

• Single point machining from 4 to 24” inches O.D. (DN100-600)

• Corrosion resistant finishes on all components to withstand harsh environments

• Hydraulic or pneumatic drive options

System Function : I.D. mount end prep machine tool with Speed Prep auto feed system designed to bevel, compound bevel, J Prep, face and counterbore pipe, fittings and valves. Also available without Speed Prep auto feed for form tooling and flange facing

System Capacity : End preps large diameter pipe from 4 to 24 inches O.D. (DN100-600), varies by application and tooling

Drive Options : Hydraulic and pneumatic, interchangeable with adaptor

Power Requirements : Hydraulic requirements 10 GPM @ 1500 PSI (38 LPM @ 103 BAR) Air requirements 95 cfm @ 90 psi (2.7 m3/min @ 6.2 bar)

Feed Method : Speed Prep auto feed system with dial control, or fully manual

Feed Rate : Variable feed rate, user adjustable

Feed Stroke : 3.5” (88.9mm) useable stroke

Construction : Lightweight aluminum housing and main shaft, high capacity bearings and load surfaces, quick deploy mandrel legs, captivated hardware

Finish : powdercoat bright red finish plus black oxide and clear coated components

Tool RPM : 0 to 20

Part Numbers:

EP 424 Pneumatic Form Tool (w/o Speed Prep) #81-000-01

EP 424 Hydraulic Form Tool (w/o Speed Prep) #81-000-02

EP 424 Pneumatic Single Point w/ Speed Prep #81-000-03

EP 424 Hydraulic Single Point w/ Speed Prep #81-000-04

Tooling : Accepts standard Wachs single point beveling and form tooling, high speed steel or carbide

Tool Slots : Rotating tool head with 3 tooling slots for simultaneous bevel, facing and counterboring. Optional single point/facing module with single slot and positive starwheel advance

Packaging : Heavy duty storage case

Dimensions : Length 12.35’’ (314mm) without mandrel, 26.75” (680mm) with mandrel, width 14.5” (368mm) at widest point (rotating tool head)

Weight : Full modular construction with each module under 70 lbs (31.75 Kg), total weight with storage case 178 lbs (80.7 Kg)

STANDARD EQUIPMENT

• Standard Mandrel

• Extension Leg Kit

• Heavy Duty Storage Case

• Operating Hand Tools

• Operating Manual

OPTIONAL EQUIPMENT

• Air Filtration for Pneumatic Drive

• Interchangeable Tooling Mounts

• Genuine Wachs Tooling