This saw has been designed for precise cutting of tubes and pipes in just seconds. For more than 40 years construction companies rely on the standard set by Orbitalum in the industrial prefabrication of pipeline systems: From the chemical, biotechnology, pharmaceutical, food and beverage industry to the energy plant construction and shipbuilding.

The basic requirement for the productive and high-quality welding of pipes with automated welding technology is a precise, right-angled and burrfree cut as well as a perfectly beveled pipe end. The GF series cuts and bevels high-alloy steel (stainless steel), low- and unalloyed steel, plastics, casting materials and non-ferrous metals easily and in just seconds, using the "Planetary Cutting" method. The powerful clamping is effected without any deformation of the workpiece.

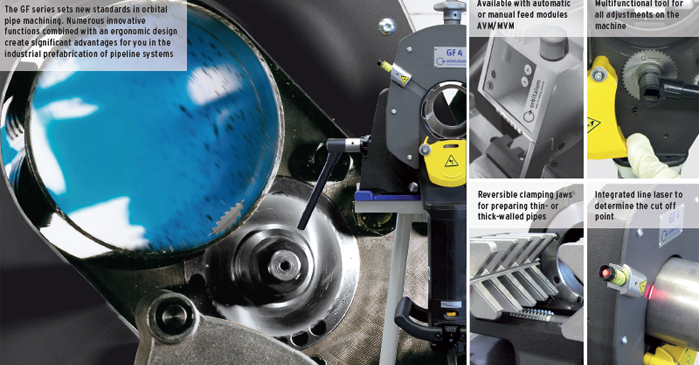

Besides the completely manual operation, users also have the possibility to choose between manual operation with manual feed module (MVM) or automatic feed module (AVM) – both optional. The latter option optimizes the cutting result, increases the tool life and reduces the operator impact. The result: Maximum safety and productivity.

• Square, burr-free and cold machining process

• Deformation-free clamping system for tubes and pipes

• Optimum preparation for the automated welding process

• Sturdy design with powerful drive

• Unique and automated orbital cutting process

• Simultaneous or seperate cutting and beveling

• Cost-effective, increasing productivity

• Long tool life

• Anthracite-colored coated components for improved sliding properties and protection against corrosion

• Stainless steel clamping attachments for protection against contact corrosion included

• Reduced operator impact by optional feed module AVM or MVM for an automated or manual cutting process

• Locking mechanism prevents unauthorized usage and theft

• An ergonomically-designed motor handle for a safe and comfortable operating position, which also enables easy cutting of elbows

• Integrated line laser to determine the cut off point

• 2 position clamping jaws to reduce chatter and enable smaller length of pipe to be machined

• Multifunctional tool for all adjustments on the machine

• Optimized speed range (40-215 rpm), ideal for cutting high-performance materials (Hastelloy®, P91, etc.)

• Swivel cable with a quick-disconnect coupler: for easy and comfortable replacement of the power cable

• Optimized saw blade guard protects the user against flying chips and comes with a measuring port (for GF 4 only)

Orbital Welding For Refrigeration Industry, Supplier, Exporter, Exporter and Supplier in Mumbai, India