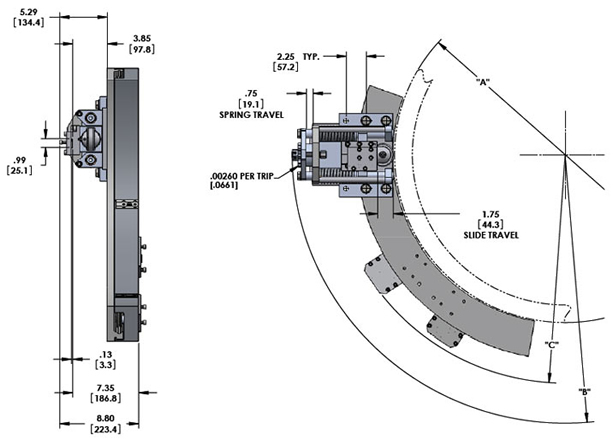

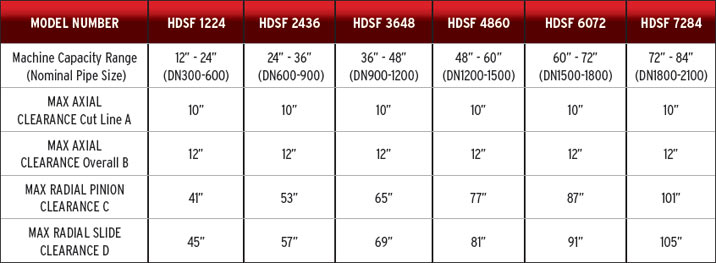

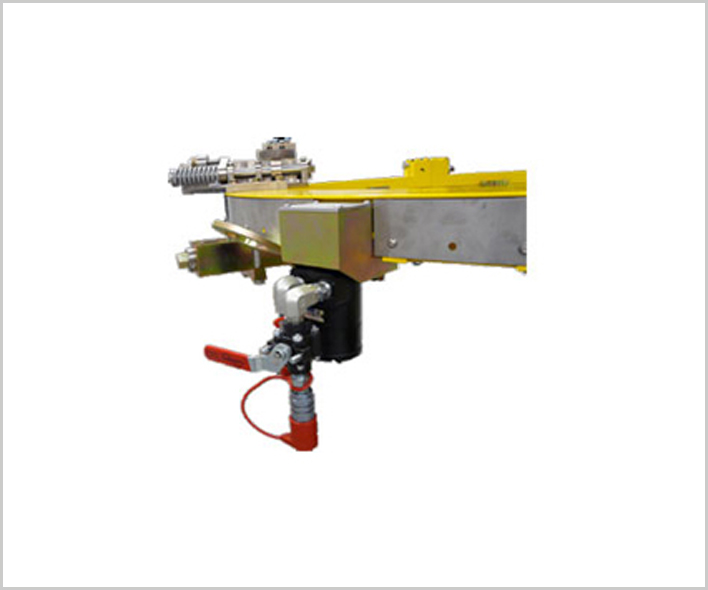

E.H. Wachs HDSF Heavy Duty Split Frame™ portable pipe cutters and bevelers are designed to part, bevel, single point, counterbore and face flanges on large diameter pipes from 12 to 84 inches O.D. (DN300-2100)*. Wachs HDSFs are available in six standard sizes to cover the most common pipe diameters, with larger sizes available by special order. The HDSF series is constructed with a bigger cross section, larger gear sets and massive hardened steel components for unrivaled durability. Powerful enough to form tool up to 1.5” (38mm) heavy wall pipe without deflection, distortion or chattering, they’re ideal for big, tough jobs where radial or axial clearances are less critical.

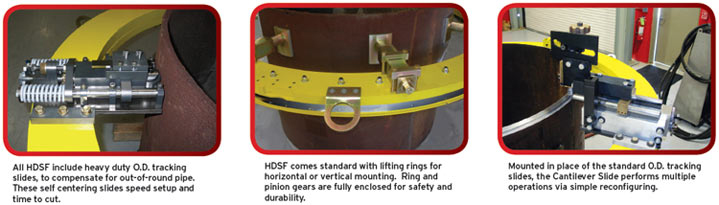

The HDSF’s run at higher rotational speeds, require less power and can handle a full 12” (305mm) range of pipe diameters per machine size. Every HDSF is equipped with spring-loaded O.D. tracking slides to compensate for deformed and out of round pipe, speeding setup and machining times. The HDSF will produce precision lathe finishes using a safe cold cutting process, which minimizes the risk of explosion on gas and petrochemical lines and eliminates a HAZ (Heat Affected Zone).

*(DN = Metric Nominal Diameter)

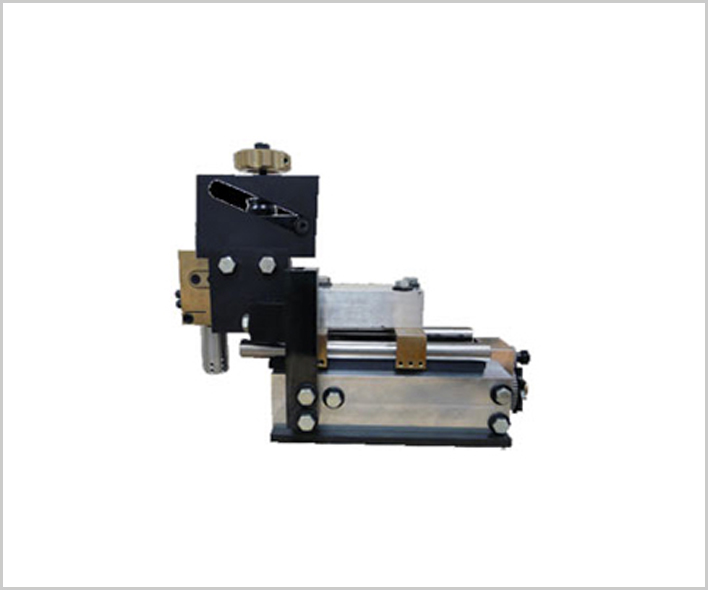

• O.D. Tracking Slides, (1) Parting and (1) Parting and Beveling

• Hydraulic or Pneumatic Drive Motor

• Ratcheting Hinge Mechanism for Scissoring Open and Closed

• Self Squaring Mounting System with Adjustable Clamping Legs

• Lifting Hooks for Vertical or Horizontal Mounting

• Heavy Duty Storage Case

• Six standard models to machine pipe from 12 to 84 inches O.D. (DN300-2100)

• 12” (305mm) range capacity between the six standard HDSF models

• Safe cold cutting process reduces risk of explosion, eliminates heat affected zone

• Lathe machining process delivers perfect compound bevels and consistent lands

• Powerful enough to form tool up to 1.5” (38mm) heavy wall pipe

• Mounts to O.D. with machine drive and slides installed, ready to operate