The ORBIWEL D TP series offers outstanding features in terms of design and functionality :

An extremely compact design has been achieved thanks to the drive motor that is fully integrated into the housing. The drive concept has made the well-known large and costly drives associated with conventional weld heads unnecessary.

• Compact design without any protrusions that would be disturbing in practice.

• Applicable with and without cold wire unit.

• Cold wire unit retrofittable for all TP weld heads.

• With the KD versions, the reel for holding the additional wire during TIG cold wire welding is also mounted on the weld head housing. This prevents an irritating twisting of the wire during the joining process.

• The cold wire feed nozzle can be adjusted exactly in both a vertical and horizontal direction.

• Open arc system.

• Infinitely variable clamping mechanism.

• Water-cooled, continuously adjustable TIG torch head allows fillet welds or short hollowed out tubes to be welded.

• The TIG torch head is secured to a slide unit that allows the position of the electrodes to be finely adjusted with great accuracy even during welding.

• Simple adjustment of the clamping unit to the pipe diameter without the need for any tools.

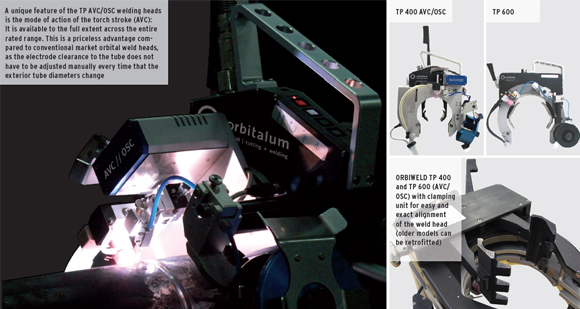

• The standard equipment of the ORBIWELD TP 250 and TP 1000 heads include clamping plates made from tool steel which ensures optimum retention to the pipe surface (very good grip properties). The ORBIWELD TP 400 and TP 600 are equipped with clamping jaws made of tempered tool steel. Besides increased clamping force, this new clamping system offers improved handling and easier and more precise alignment of the weld head on the pipe. Clamping jaws for stainless steel applications are optionally availabe. The new clamping unit can be upgraded for older TP 400 and TP 600 models.

• TP weld heads are easily centered to the tube and clamped in place with the help of a clamping lever.

• No additional remote control is required thanks to the keys integrated directly into the weld head housing.

• With oscillation (OSC) and arc voltage control (AVC) â only applicable in combination with the orbital welding power supply ORBIMAT 300 CA AVC/OSC.

• The arc length is kept at a constant gap mechanically; with AVC/OSC versions the constant gap is kept automatically.

• Can be used for thick wall pipes (multiple layer welds).

• Including a motorized travel option for the TIG torch across the nominal diameter, so that no additional mechanical basic presetting is required for any change in the tube diameter.

• Max. oscillation of the torch: 20 mm (0.787").

• Directly on the weld head mounted cold wire feed unit with retainer for à 100 mm/1 kg (3.937"/2.2 lbs) wire coil.

Orbital Welding For Bend Tubes, Open Orbital Weld Heads, Supplier, Exporter, Exporter and Supplier in Mumbai, India